Description

Laminating Machine FX Diamond CFL. Description:

The new laminating machine from Veit – Fx Diamond CFL is the ideal solution for gentle laminating of flexible materials, such as leather, and textiles cuttings of foam, felt, non-woven or knit materials.

The FX Diamond CFL laminating machine can be used for:

- Leather;

- Textiles;

- Technical textiles;

- Film layers;

- Carbon fiber;

- Filtration materials;

- Industrial materials;

- Medical supplies;

- Construction materials.

In order for the lamination result to be a perfect one, it is necessary to have a precise control between the most important parameters of this process: TEMPERATURE and PRESSURE. In order to have this control, VEIT has developed a new innovative temperature control system that measures temperature directly from the band level.

The temperature is set at the beginning of the process and can be maintained at a constant level throughout the working process. Also the temperature can be controlled very precisely through the touch-screen display.

The machine has an innovative FLEXO system that allows the processing of a wide range of materials of different sizes ensuring a perfect and long-lasting lamination process. This innovative system significantly reduces compression of delicate fabrics and ensures a higher quality of the final result.

FX DIAMOND CFL laminating machine is very easy to use, so the training for using this machine is realized in a very short time and all the important and basic options of the machine are immediately learned by the operator.

Apart from the fact that the machine is very simple to use, it also has a perfect service design that allows regular and constant cleaning without too much intervention.

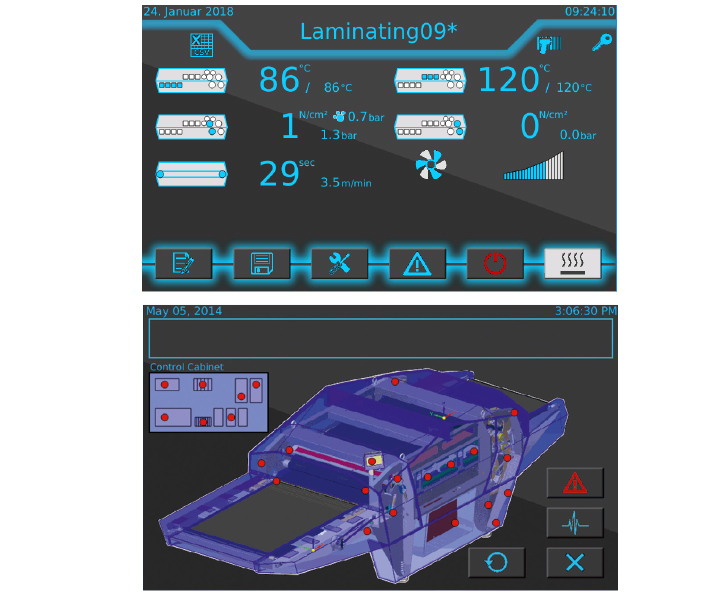

The control panel:

The touchscreen control allows the adjustment and control of all necessary parameters:

- Indication of set/actual temperature of the different heating zones;

- Parallel display of laminating time (sec) and speed (m/min);

- Parallel display of pressure in bars and N/cm²;

- Fill level indicator for optional stacking device;

- Self-diagnosis system with immediate error message (visual and acoustic);

- Visual machine availability via signal lamp green/red;

- Storing of different programs which can be run when required;

The operator can save up to 200 programms on this device. Optionally the identification of the laminating items can be made trough a hand held scanner.

The pressing process is a crucial factor when it comes to laminating where high quality and permanent bonding are required.

The FLEXO Double Pressure system allows laminating materials of different types and thicknesses. The FLEXO rollers adapt perfectly to the surface and are modeled according to the thickness of the materials by plane pressing – unlike other conventional systems that act by linear pressure. Structural surfaces such as leather materials remain intact after the rolling process.

The Heating System:

To achieve a perfect lamination, the exact temperature setting is required depending on the materials used. The FX Diamond CFL offers the possibility to choose from a very wide range of combinations of requirements and temperatures so that the final result is the best in terms of quality.

The heating system of the FX Diamond CFL laminating machine comes with the following advantages:

- The resistors are made of aluminum and have the following benefits: they distribute heat perfectly throughout the width of the machine, the heat transfer to the laminated material is made in the most efficient way ensuring a very low energy consumption;

- Two heating zones, that allow the temperature to be adjusted separately – for perfect results;

- Precise temperature control guarantees uniformity between the set and the actual temperature. The accuracy of the temperature is due to a sensor placed directly on the heated belt;

- The resistors have a curved shape in order to be in permanent contact with the belt and thus store a reduced amount of energy, the temperature being transmitted directly to the material.

The FX Diamond CFL is available in the following versions:

- FX Diamond CFL 1000 (working width 1000 mm);

- FX Diamond CFL 1400 (working width 1400 mm);

- FX Diamond CFL 1400 L (working width 1400 mm, extended heating zone);

- FX Diamond CFL 1600 (working width 1600 mm).

Reviews

There are no reviews yet.