Description

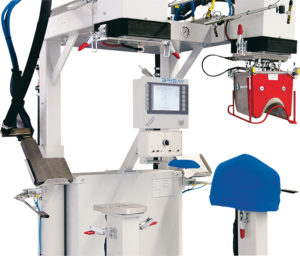

Shoulder Finish Pressing Machine BRISAY 1920-101 Premium. Description:

This shoulder finish pressing machine is equipped with 2 head bucks and 2 lower bucks offering an optimal fit according to different shoulder styles for the pressing of left and right shoulders.

The press consists of a powerful 230 V motor that has a production capacity of approximately 90 pieces per hour. The functions of the press are activated by the pedals from the base. The machine has a double pedal for individual action of absorption and blowing functions.

Due to the DMC system (direct control of the machine), which is found on all Brisay presses, the waiting time for starting the machine has been eliminated. Even in case of emergency or power outages, the machine is ready for operation in less than 1 second.

The special buck design (accommodates all independent sizes): For overlapping pressing.

Optionally the press can be equipped with a rapid exchange system for bucks, thus ensuring a flexible and quick solution to changes in fashion trends and an additional set of bucks for different shoulder styles.

Also, as an option, the press can come with a buck heating unit – the additional set of bucks are pre-heated and can pe used immediately after changing thus increasing the productivity.

The digital distance control ensures a very precise adjustment of the distance between the bucks to avoid marks and shine on all types of fabric (optional).

The blowing device in collar area: Leaked steam is blown away avoiding steam marks, touch-up work is reduced (optional).

Designed to guarantee operator safety, BRISAY 1920-101 Premium has a function that immediately stops the machine in case of emergency. After activating this function the press immediately depressurizes and remains inactive until it receives the next command.

The control panel:

The press contains a control panel with a power of 400 MHZ , a user-friendly 5.7“ colour touch display, a USB port and WLAN interface that allow remote control of the machine.

This panel directly monitors the electrical components of the press and announces when an error occurs, thus the operator intervenes directly where the problem is without wasting time on diagnostics. In order to facilitate the work of the operators, the control panel keeps a history of the errors that have occurred.

The control unit has a storage capacity of 200 programs and comes with 3 factory pre-stored sample programs: soft, medium and hard.

The press consists of a pair of bucks, one pair for each shoulder, left and right, there is the possibility of automatically transferring a program from one pair to another, the work program will be operated only for one pair and transferred identically to the other. This increases productivity and streamlines working time.

The control panel has a separate work program selection switch that allows for quick change of programs as needed. In addition, it is possible to operate two different programs at the same time, which leads to a considerable increase in productivity.

The press is equipped with an automatic program stepping: automatic transfer of the program from one machine side to the other.

Veit ironing bucks are made of the highest quality materials ensuring an even distribution of steam and vacuum power onto the entire pressing surface.

You can find all types of bucks and other accessories or consumables shown below or on our shop website www.texco.ro.

Advantages of BRISAY 1920-101:

- 2 Head bucks and 2 lower bucks: Optimal fit according to different shoulder styles for the pressing of left and right shoulders;

- Special buck design (accommodates all independent sizes): For overlapping pressing;

- Rapid exchange system for bucks: For a flexible and quick solution to changes in fashion trends / Bucks can be easily changed within few minutes / Increases productivity;

- Additional set of bucks: For different shoulder styles (optional);

- Buck heating unit: Additional set of bucks is pre-heated and can be used immediately after changing / Increases productivity (optional);

- 2 back holding arms: Pressing garment is held during the pressing operation;

- User-friendly 5.7“ colour touch display;

- Separate program selection switch: Allows quick change of programs;

- Manual operation possible;

- Intermediate jacket hanging device: During cooling of the pressing garment the program stepping device is activated / Increases quality / Increases productivity;

- Automatic program stepping: Automatic transfer of the program from one to the other machine side / Increases productivity;

- Optional tandem operation: 2 different programs at the same time;

- Digital distance control: Very precise adjustment of the distance between the bucks to avoid marks and shine on all types of fabric (optional);

- Blowing device in collar area: Leaked steam is blown away avoiding steam marks, touch-up work is reduced (optional).

Reviews

There are no reviews yet.